Simple. Yet Robust.

The MTF Process

Sourcing

Good yarn will lead to good fabric and good fabric will result in a good shirt. This is the philosophy that guides us to source from the best that is available. We have built relationships with our suppliers to not only ensure quality but timely deliveries so that our commitments to our buyers are met.

Weaving

We use both rapier and projectile technologies which are most appropriate for weaving shirting fabrics allowing usage of multiple colours and the most intricate designs.

Processing & Dyeing

This is sourced out to specialist process houses depending on the composition of the fabric giving the perfect finish and colour matching.

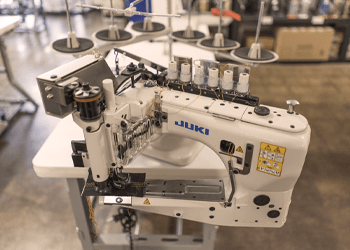

Full Package

We are a solution provider to brands wherein we develop the complete shirt or blouse with our design inputs where required. The package includes all labels and tags with price kimbals so that the garment can go directly to the retail outlets.